The Origin and Structural Revelation of the Auger Bit

The Auger Bit, a crucial member of the drilling family, has a history tracing back to ancient times. It is not merely a simple "hole-digger" but a sophisticated design blending engineering mechanics and material science. Understanding the core principles of this drill bit is fundamental to selecting and utilizing it effectively.

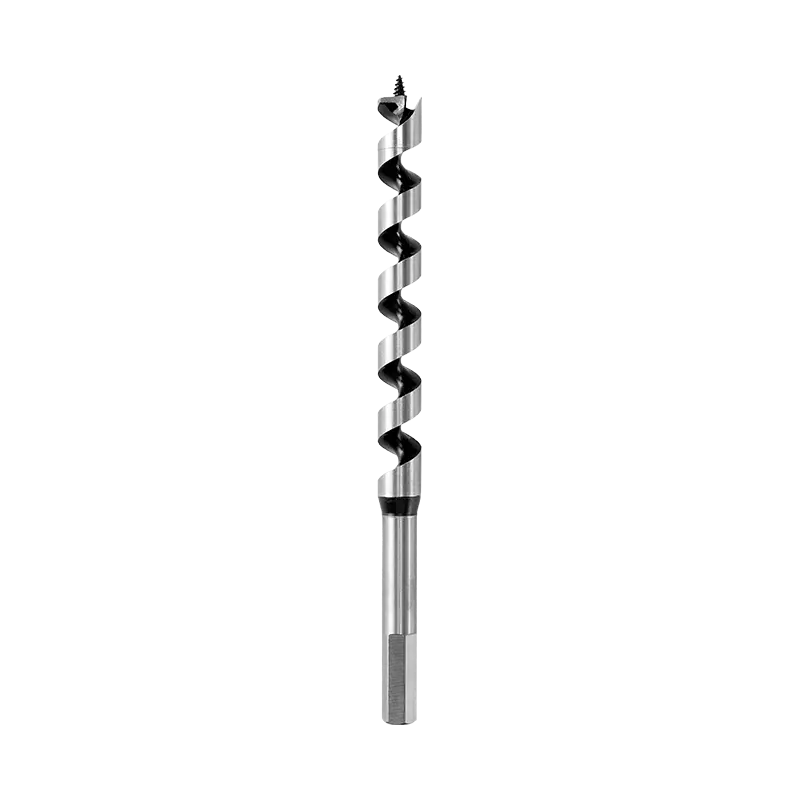

Core Structure: The Spiral Flute and Cutting Edge

The signature feature of this drilling instrument is its spiral flute. This helix structure is not just for aesthetics; it serves two critical functions:

- Efficient Chip/Soil Ejection: During the drilling process, the cut material (wood chips, soil, or ice) must be swiftly extracted from the hole to prevent clogging and reduce friction-induced heat. The precise angle and pitch of the spiral flute are calculated to lift the cuttings upward with minimal resistance.

- Guidance and Stability: The helical body provides lateral support during operation, helping to maintain the verticality and accuracy of the bore.

At the tip is the cutting edge, the crucial part that performs the actual material removal. For woodworking applications, the tip often features a feed screw (or pilot point). This screw quickly “bites” into the wood, pulling the instrument into the work, significantly reducing the pressure required from the operator and providing accurate positioning.

Different Applications for the Spiral Drill Tool

The versatility of the spiral drill tool lies in its specialized designs tailored to different materials and applications.

Drill Tools for Wood (Wood Drilling Instruments)

- Paddle Bits/Spade Bits: Although not typical helical designs, they are commonly used for rapid drilling in wood, offering high efficiency but a rougher bore wall.

- Traditional Ship Augers: Featuring long, deep spiral grooves, these are ideal for deep-hole drilling in heavy timbers and ship wood, possessing exceptionally strong chip evacuation capabilities to handle moist wood.

- Fine Woodworking Drills (Arkansas Pattern): Specifically designed for precision joinery, capable of producing very smooth bore walls.

Earth Drilling Systems for Soil (Ground Augers)

Earth spiral drill tools are commonly used in gardens, farms, or construction sites for digging post holes, planting trees, or setting fences.

- Structural Characteristics: Compared to woodworking models, these systems are typically more robust, with wider spirals and a larger pitch to efficiently move soil, gravel, and small stones. They are usually paired with high-torque Power Heads.

- Application Examples: Small manual or electric post-hole diggers, and large hydraulic drills attached to tractors or excavators.

Ice Drills for Ice and Snow (Ice Augers)

The ice drill is a specialized branch of this tool, primarily used for ice fishing.

- Structural Characteristics: The blade angle is designed to efficiently bring ice shavings out of the water surface. The sharpness of the blades is extremely critical for quickly cutting through hard ice layers.

The Science and Technology Behind High-Quality Auger Bits

Auger Bits' service life and drilling performance are almost entirely dependent on their manufacturing process and the application of material science.

Materials and Heat Treatment Process

High-quality Auger Bits, especially those intended for hard materials or high-strength applications, must be made from high-carbon steel or alloy steel.

- Steel Selection: Ensures the drill bit possesses the necessary hardness and toughness during high-speed cutting. If too hard, it becomes brittle; if too soft, the cutting edge dulls quickly.

- Heat Treatment: Precise quenching and tempering are key. This involves heating the steel to extremely high temperatures, rapidly cooling it, and then reheating it slowly to optimize the steel's crystalline structure, balancing hardness with impact resistance.

Surface Treatment and Precision Machining

Modern drill bits often utilize surface treatments like nitriding or chrome plating to enhance their wear resistance and corrosion resistance, particularly for those used in outdoor or damp environments. The precision machining, especially the grinding process, of the spiral flutes directly determines their chip evacuation ability and the smoothness of the drilling operation.

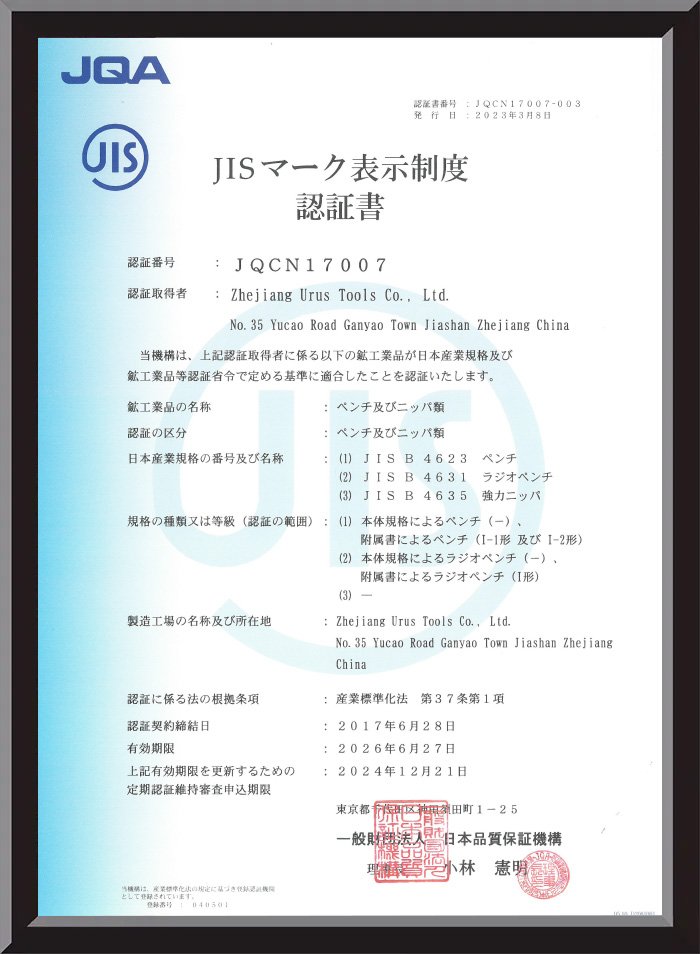

While the specialized field of the Auger Bit continues to advance with engineering science, the industry's leaders are constantly engaged in technological innovation. As part of our continuous business development and commitment to excellence in tool manufacturing technology, our company was awarded a national high-tech enterprise, Jiaxing patent model enterprise, Municipal R&D center, Famous trademark, Civilized enterprise, and so on. These qualifications not only acknowledge our investment in technological research and intellectual property protection but also serve as the driving force for our continuous pursuit of excellence and the delivery of high-quality products in the field of precision tools.

Maintenance and Future Trends: Keeping Your Auger Bit Efficient

Daily Maintenance and Troubleshooting

- Keep It Sharp: A dull cutting edge is the biggest factor affecting the efficiency of this drilling instrument. Regular sharpening using specialized tools is crucial.

- Cleaning and Lubrication: After use, all cuttings or soil must be removed, and a small amount of rust-preventive oil should be applied, especially to the flutes and cutting edges, to prevent rust.

- Common Issues: Clogging in the spiral groove is usually due to improper drilling speed or insufficient chip evacuation. When using deep-hole drill systems, the tool should be regularly withdrawn to clear the cuttings.

The Future of Intelligence and Material Innovation

In the future, the design of Auger Bits may incorporate more simulation technology to optimize the flute shape, further enhancing chip evacuation efficiency and reducing energy consumption. The application of new composite materials and superhard coatings will enable this tool to handle more challenging environments, such as drilling operations involving high-strength minerals or specialized construction materials.

中文简体

中文简体 English

English русский

русский