Don't hesitate to send a message

I. Introduction: Solving the "Impossible" Task The phrase "fitting a square peg into a round hole" is a universal symbol...

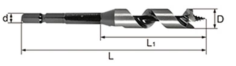

READ MOREDrill rods are a kind of products that require relatively high precision. They are widely used in mines and coal mining industries. They are all operated in places where the environment is relatively difficult. The quality issues are most important to everyone. However, in the process of use , There will definitely be damage, and at this time you need to understand the adjustment and anti-corrosion skills of the drill rod. If you understand these contents, when the equipment needs to be reorganized, you can make adjustments in time to make the work go on normally.

The biggest problem that it is difficult for our threaded drill rods to enter the international market, except for the quality and life of the drill rods, is the poor straightness. Because the threaded drill rod goes through many processes in the production process, the hoisting, transportation and processing of these processes often increase the bending of the drill rod, so the drill rod is straightened before the anti-corrosion treatment to ensure the straightness of the drill rod Meet the requirements of the product size, that is, less than 1 mm/m. The main purpose of finishing is to improve the straightness of the threaded drill rod. The straightness of the drill rod is very important to ensure the drilling efficiency of the drill rod, reduce the bending fatigue stress and the appearance quality.

The anti-corrosion treatment of the drill rod, because the threaded drill rod works under the premise of high frequency, high stress and water erosion, especially the inner hole of the drill rod, usually 1.5MPa water is passed through, and the water has a larger flow rate in the inner hole, so The inner hole of the drill rod easily forms an erosion pit and causes the fatigue source. After the fatigue source is formed, the corrosion fatigue crack growth rate is also very high, which is the main reason for the internal fatigue fracture of the threaded drill rod. The commonly used anti-corrosion treatment is phosphating. After phosphating, the holes are sealed with earth wax. Before phosphating, the inner hole and outer surface of the drill rod are processed by sandblasting or shot blasting. Because the phosphating layer is a honeycomb structure with strong adhesion to the surface of steel, it is sealed with terra wax, which has strong hydrophobicity, so it isolates the corrosive effect of water on the inner pores. The anti-corrosion work of this kind of products is very important. If the equipment can be used for a long time, anti-corrosion measures must be taken in time!

I. Introduction: Solving the "Impossible" Task The phrase "fitting a square peg into a round hole" is a universal symbol...

READ MOREMetalworking has always been a cornerstone of industrial development, shaping everything from automotive components to a...

READ MORE1. What Are Waterpump Pliers? – The Flexible “All-Rounder” Tool In modern industrial manufacturing and daily maintenance...

READ MORESelecting the appropriate industrial cutting tools is a critical decision that directly impacts manufacturing efficiency...

READ MORE+86-573-84611229

+86-573-84611518

NO.35 Yucao Road, Ganyao Town, Jiashan City, Zhejiang Province, China